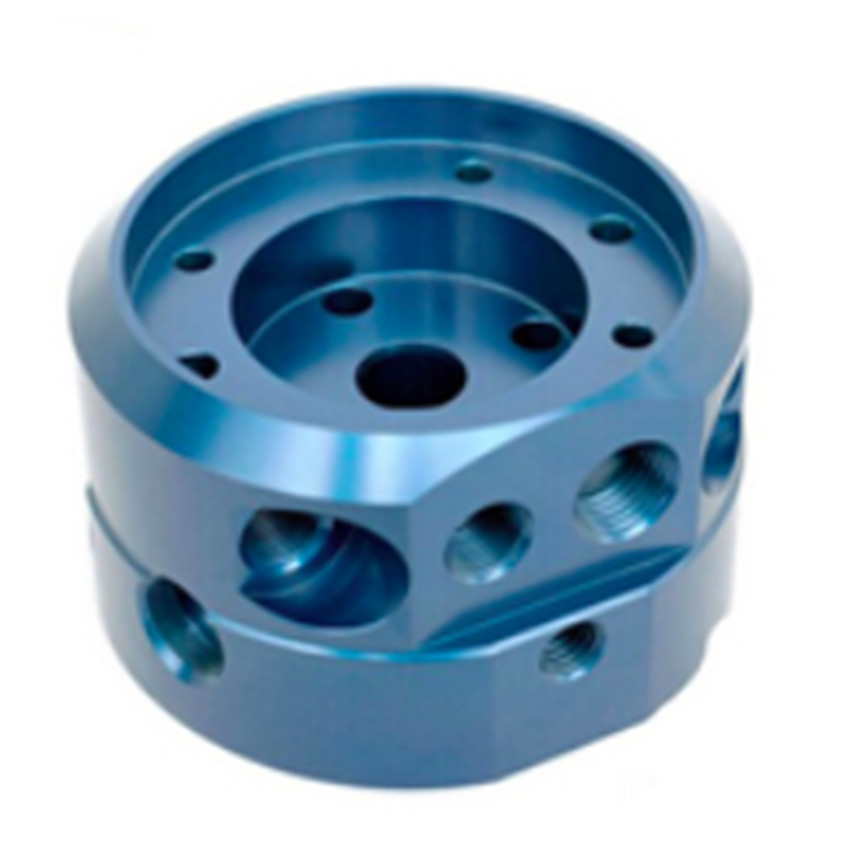

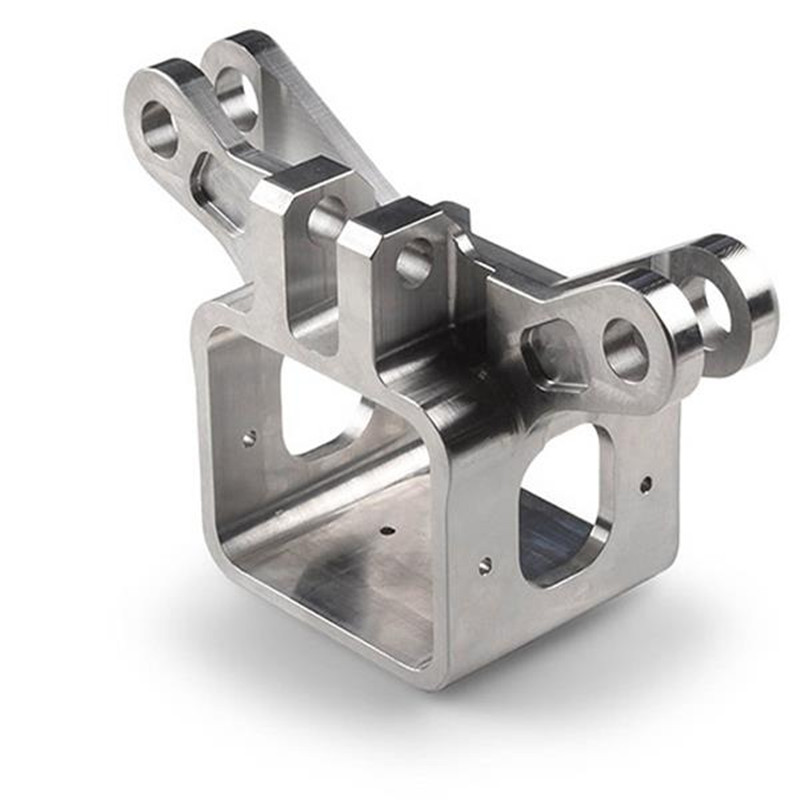

Vaega u'amea titanium Vaega Ta'avale/Mea oneone oneone/Masini uamea/Masini/Vaega afi mo Compressor Tino

| Meafaitino | Alumini: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Uamea leila: SS201, SS301, SS303, SS304, SS316, SS430 ma isi | |

| Uamea: u'amea malu / carbon sila e aofia ai 1010, 1020, 1045, 1050, Q690 etc | |

| 'apamemea: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 ma isi. | |

| Kopa: C11000, C12000, C12000, C17200, C72900, C36000 ma isi. | |

| Fa'agasologa | Siamani Trumpf ituaiga Laser tipi, CNC sele masini, CNC punou masini, |

| (CNC) faʻailoga masini, Hyraulic Machine, Faʻailoga eseese masini, CNC nofoaga tutotonu. | |

| Laufanua | Alumini: Anodization, Sandblast, Brushing, Polishing, Electro-plating etc |

| u'amea u'amea: fa'alelei, pulumu, fa'asa'o, Sandblasting, fa'apipi'i eletise | |

| Uamea: fa'apipi'i zinc, fa'apipi'i nikeli, fa'apipi'i Chrome, fa'a'u'u pa'u, vali ma isi | |

| 'apamemea & 'apa: Fufulu, Faila ma isi | |

| Sa'o | + - 0.1mm |

| Fa'atatauga | Auala, Taavale, Ta'avale, Fomai, Masini, Meafaigaluega, Fa'aeletonika, Eletise ma isi |

Titanium o se ituaiga u'amea fou.O le faʻatinoga o le titanium e fesoʻotaʻi ma mea o loʻo i totonu o mea leaga e pei o le carbon, nitrogen, hydrogen ma le okesene.O mea o loʻo i totonu o le faʻaleagaina o le titanium iodide mama e itiiti ifo i le 0.1%, ae o lona malosi e maualalo ma e maualuga le palasitisi. O meatotino o le 99.5% titanium mama alamanuia e faʻapea: density ρ = 4.5g / cm3, faʻafefeteina 1725 ℃, conductivity vevela λ = 15.24W / (mK), malosi tensile σb = 539MPa, elongation δ = 25%, vaega shrinkage ψ = 25%, modulus o elasticity E = 1.078 × 105MPa, maaa HB195.

Malosi maualuga

O le mamafa o le uʻamea titanium e masani lava e uiga i le 4.51g / cm3, naʻo le 60% o le uamea, ma o nisi o faʻameamea titanium malosi maualuga e sili atu i le malosi o le tele o uʻamea faʻapipiʻi. nai lo isi mea faʻapipiʻi uʻamea, lea e mafai ona maua ai vaega e maualuga le malosi o le iunite, faʻamalosi lelei ma le mamafa mama. Vaʻalele afi afi vaega, auivi, paʻu, faʻamau ma mea faʻapipiʻi faʻaoga uma titanium alloy.

Malosi vevela maualuga

O le faʻaaogaina o le vevela o ni nai selau tikeri maualuga atu nai lo le alumini alumini, e mafai lava ona faatumauina le malosi manaʻomia i le vevela vevela, e mafai ona galue mo se taimi umi i le 450 ~ 500 ℃ vevela.O nei ituaiga e lua o uʻamea titanium i le 150 ℃ ~ 500 ℃ laina o loʻo i ai pea se malosi faʻapitoa maualuga, ma o le alumini alumini i le 150 ℃ malosi faʻapitoa na faʻaitiitia ai le malosi. 200℃.

Lelei tetee i le pala

E sili atu le lelei o le pala o le u'amea titanium nai lo le u'amea u'amea i le ea susu ma le sami water.Pitting corrosion, corrosion acid, popole corrosion teteʻe e sili ona malosi; E sili ona lelei tetee corrosion i alkali, chloride, chlorine oloa organic, nitric acid , sulfuric acid, etc.Ae o le corrosion resistance o le titanium i le faʻaitiitia o le okesene ma le chromium e le lelei.

Lelei maualalo le vevela faatinoga

Titanium alloy e mafai ona tausia ana mea faʻainisinia i le maualalo ma ultra-maualalo temperatures.Titanium alloys ma lelei maualalo le vevela faatinoga ma matua maualalo elemene interstitial, e pei o le TA7, e mafai ona faatumauina se palasitika faapitoa i -253 ℃. O le mea lea, o le titanium alloy e taua foi. maualalo le vevela mea faufale.

Gaoioiga kemikolo maualuga

O mea fa'amea fa'ameamea titanium

O mea fa'amea fa'ameamea titanium

O le Titanium o loʻo i ai se gaioiga faʻamalosi malosi ma le O2, N2, H2, CO, CO2, vai ausa, amonia ma isi kasa i totonu o le atemosifia. Pe a sili atu le carbon content nai lo le 0.2%, o le TiC faigata o le a faia i le titanium alloy. e maualuga le vevela, o le a fausia le vaega maaa o le TiN e ala i le fegalegaleaiga ma N.A oo i le vevela i luga atu o le 600 ℃, o le titanium e mitiia le okesene ma fausia ai se vaega faʻamaʻa ma le maualuga maualuga. fomu foʻi.O le loloto o le maaa ma brittle luga layer e maua mai i le absorption o le kesi e mafai ona oʻo atu i le 0.1 ~ 0.15 mm, ma le tikeri faʻamaʻaʻaina o le 20% ~ 30%. E tele foi le vavalalata o vailaʻau Titanium, faigofie e maua ai le faʻapipiʻi ma le feteʻenaʻiga. luga.

Laiti elasticity conductivity vevela

O le vevela o le titanium (λ=15.24W/(m·K)) e tusa ma le 1/4 o le nickel, 1/5 o le uʻamea, 1/14 o le alumini, ma le vevela o le titanium eseese. alloys e tusa ma le 50% maualalo ifo nai lo le titanium.O le modulus elastic o titanium alloy e tusa ma le 1/2 o le uamea, o lona uiga e le lelei lona malosi, faigofie ona deformation, e le tatau ona faia i slender rod ma vaega manifinifi-pa puipui, tipi pe a o le faagasologa o le pito i luga o le rebound e tele, e uiga i le 2 ~ 3 taimi o le uamea stainless, e mafua ai le feteʻenaʻiga ogaoga, faʻapipiʻi, faʻapipiʻi ofu i luga o le meafaigaluega.